Resources

Learn more about chain grading

Chain Data

About Grades

Chain Strength Chart / Working Load Limit Comparisons

Chain strength is identified throughout our website by Working Load Limits* (WLL) in pounds

- the higher the WLL, the stronger the chain.

*WLL is sometimes called Safe Working Load (SWL)

| Chain Size | Grade 30 Proof Coil (WLL in lbs) Specs prices |

Grade 43 High Test (WLL in lbs) Specs prices |

Grade 70 Transport (WLL in lbs) Specs prices |

Grade 80 Alloy (WLL in lbs) Specs prices |

Grade 100 Alloy (WLL in lbs) Specs prices |

|---|---|---|---|---|---|

| 1/8 | 400 | - | - | - | - |

| 3/16 | 800 | - | - | - | - |

| 7/32 | - | - | - | 2,100 | 2,700 |

| 1/4 | 1,300 | 2,600 | 3,150 | - | - |

| 9/32 | - | - | - | 3500 | 4300 |

| 5/16 | 1,900 | 3,900 | 4,700 | 4,500 | - |

| 3/8 | 2,650 | 5,400 | 6,600 | 7,100 | 8,800 |

| 7/16 | 3,700 | 7,200 | 8,750 | - | - |

| 1/2 | 4,500 | 9,200 | 11,300 | 12,000 | 15,000 |

| 5/8 | 6,900 | 13,000 | 15,800 | 18,100 | 22,600 |

| 3/4 | 10,600 | 20,200 | 24,700 | 28,300 | 35,300 |

| 7/8 | - | 24,500 | - | 34,200 | - |

| 1" | 17,900 | 30,000 | - | 47,700 | - |

| 1-1/4 | - | - | - | 72,300 | - |

| Definitions: | |||||

| Proof Load: 2 x WLL | CAUTION: | ||||

| Breaking Strength: 4 x WLL (exception Grade 43 is 3 x WLL) | ONLY USE WLL FOR DESIGN PURPOSES. | ||||

Grade 30 Proof Coil

A general purpose chain of standard commercial quality. Made from low carbon steel, this chain is frequently used for fabricating tow chains, logging chains and, when appropriate, tie down or binding chains. Hallmarked every 3 feet or less on sizes over 5/16 with manufacturers symbol and grade marking: 3, 30, or 300.

Not for overhead lifting.

BBB Anchor Chain

A compact (short) link chain of standard commercial quality. Made from low carbon steel, this chain is used primarily for boat windlasses when hot galvanized. Hallmarked every link with "3B". Not for overhead lifting.

Not for overhead lifting.

Grade 40 High Test

Strength levels are the same as Grade 43 but the dimensions of the chain links are smaller using ISO standards. Primarily used for boat windlasses, this grade has become a standard for that industry. The Grade 40 designation was exclusively used by ACCO Chain until 2005 to designate their High Test grade chain. They now use "43" in keeping with the rest of the industry. The chain is hallmarked "G4" on every link. Not for overhead lifting.

Not for overhead lifting.

Grade 43 High Test

This is a higher strength chain used for years in the trucking industry for tie downs that meet DOT specifications. Made from a higher carbon steel, its strength surpasses proof coil working load limits, size for size, by a factor of 2 to 1. Hallmarked every 1 to 3 feet with manufacturer's symbol and grade marking: 4, 40, 43 or 400. Not for overhead lifting.

Not for overhead lifting.

Grade 70 Transport

As its name implies Transport Chain is used primarily to tie down loads on over-the-road equipment. The yellow chromate (gold) plating makes it easily recognizable even from a distance. Made from heat-treated carbon steel it has about 25% more strength than high test chains. Hallmarked every 1 to 3 feet with manufacturer's symbol and grade marking: 7, 70 or 700. Not for overhead lifting.

Not for overhead lifting.

Grade 80 Alloy

The first chain specifically designed for safety and approved by OSHA and other agencies for overhead lifting. Its alloy, heat-treated steel makes it ideal for making lifting slings and heavy duty tow chains. Hallmarked no more than 3 feet apart with manufacturer's symbol and grade marking: 8, 80 or 800. Suitable for overhead lifting.

Suitable for overhead lifting.

Grade 100 Alloy

This new innovation in alloy chain metallurgy provides about 25% higher working load limits over Grade 80 chain with some limitations reported in lower ambient temperatures. Hallmarked no more than 3 feet apart with manufacturer's symbol and grade marking: 10 or 100. Listed as suitable for overhead lifting.

Listed as suitable for overhead lifting.

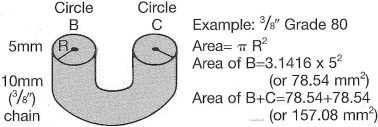

The Meaning of Chain Grade Numbers

The chain grade numbers which manufacturers use are actually one tenth of the actual grades. Therefore, our grade 80 is 800, grade 70 is 700, and so on

The grade refers to the tensile strength of the chain. This is expressed in newtons per square millimeter (a newton is approximately 0.224805 lbs). The tensile strength is calculated by multiplying the grade times the area of the two cross sections of a link (see left).

(Area) 157.08 mm2 x 800 n (Grade)=125,664 newtons ultimate breaking strength 125,664 newtons x .224805=28,250 lbs ultimate breaking strength 125,664 newtons÷1000=125.66 kn (Kilonewtons)

Sling Specs

Grade 100 Alloy Working Load Limits (lbs) for Chain Slings

According to NACM Welded Steel Chain Spec

| Chain Size |

Single Leg |

Double Leg |

Double Leg |

Double Leg |

Triple or Quad Leg¹ |

Triple or Quad Leg¹ |

Triple or Quad Leg¹ |

|---|---|---|---|---|---|---|---|

| 7/32 | 2,100 | 3,600 | 3,000 | 2,100 | 5,500 | 4,400 | 4,400 |

| 9/32 | 4,300 | 7,400 | 6,100 | 4,300 | 11,200 | 9,100 | 6,400 |

| 3/8 | 8,800 | 15,200 | 12,400 | 8,800 | 22,900 | 18,700 | 13,200 |

| 1/2 | 15,000 | 26,000 | 21,200 | 15,000 | 39,000 | 31,800 | 22,500 |

| 5/8 | 22,600 | 39,100 | 32,000 | 22,600 | 58,700 | 47,900 | 33,900 |

| 3/4 | 35,300 | 61,100 | 49,900 | 35,300 | 91,700 | 74,900 | 53,000 |

| 7/8 | 42,700 | 74,000 | 60,400 | 42,700 | 110,900 | 90,600 | 64,000 |

| 12 | 47,700 | 82,500 | 67,400 | 47,700 | 123,800 | 101,000 | 71,500 |

| 1-1/42 | 72,300 | 125,200 | 102.200 | 72,300 | 187,800 | 153,400 | 108,400 |

| 1 Since at most three legs can support the weight of any load, Triple and Quad leg slings both have the same working load limits. | |||||||

| 2 1" and 1-1/4 available only in Grade 80 alloy | |||||||

D.O.T. Specs

Effective Date Sep 27, 2002, Compliance date Jan 1, 2004

Detailed information on securing loads for safe transportation from the US Dept of Transportation

For clarification: USDOT Cargo Securement Enforcement Policy Dec 31, 2003